WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Calcium carbonate crushing plant process is very simple, it is the use of crushing, transportation, industrial milling equipment containing calcium carbonate mineral raw materials for processing, can be used in the equipment are jaw crusher, calcium carbonate milling machines, conveyors, etc. .

After the calcined lime has been slaked with water, the resulting milk of lime is purified and carbonated with the carbon dioxide obtained from the calcination process. SBM is a world leading calcium carbonate processing machine supplier. We also provide used calcium carbonate processing machine, including quarrying plant, mining equipment ...

These similar products actually have a strikingly different influence on your soil. The primary difference lies in the use of magnesium: Dolomite lime contains large amounts of magnesium along with calcium carbonate while calcitic lime only contains calcium carbonate. Magnesium is an important mineral for plant .

geological source of the limestone determines how much calcium carbonate and magnesium carbonate is in a ton of lime. The amount of these two carbonates determines the total neutralizing value (TNV) of the limestone. The processing of the limestone determines the fineness of the particles in .

Calcium Carbonate Manufacturing Plant Heavy calcium carbonate, also known as grinding calcium carbonate, is made by directly crushing natural calcite, limestone, chalk, .

Calcium carbonate processing plant is a calcium carbonate production line to make ground calcium carbonate powder. Usually, limestone or marble will serve as the basis material. The plant will be equipped with calcium carbonate grinding mill to gr...

Among lime plants technology, we cater for Hydrated Lime Plants, Quick Lime Plants and Precipitated Calcium Carbonate Plant. We offer lime plants including lime processing plant and lime processing machinery that incorporate the latest technology ensuring efficient functioning & optimum output.

Calcium Carbonate Limestone Processing Plant. We common folk to one kind of limestone, which is mainly through high-temperature calcination of limestone, but this is relatively simple manufacturing methods. With the acceleration of the industrialization process, this small workshop production has been unable to meet the massive demand and the ...

The process of calcination derives its name from the Latin calcinare (to burn lime) due to its most common application, the decomposition of calcium carbonate to calcium oxide and carbon dioxide, in order to create cement.The product of calcination is usually referred to in general as "calcine", regardless of the actual minerals undergoing thermal treatment.

Calcite is a form of calcium carbonate, a type of calcium salt oxide with three atoms of oxygen bonded to one atom of calcium. Calcite binds with other compounds to create limestone which is used in construction. When using these substances as building materials, the differences between calcite and limestone become clear.

Jun 10, 2008· When limestone is suggested as a source of calcium for the plant, it is usually the exchangeable calcium left over from the reactive lime fraction. Research at Michigan State University tested the effect that a dolomitic limestone had on pH and calcium concentrations for the first four weeks after mixing (Figure 1).

CaCO3 Calcium Carbonate Processing Plant Posted: 2015-08-05. CaCO3 (Calcium Carbonate) and its usage: Calcium carbonate is a chemical compound with the formula CaCO3. It is a common substance found in rocks in all parts of the world, and is the main component of shells of marine organisms, snails, coal balls, pearls, and eggshells.

Mar 13, 2018· and waste lime from sugarbeet processing plants, kiln dust from cement manufacturing plants, and waste lime from acetylene manufacturing facilities. Click to expand... In my area, we have quarries that mine either calcium carbonate or magnesium carbonate (Dolomite).

Jul 07, 2017· Limestone – Its Processing and Application in Iron and Steel Industry. Limestone is a naturally occurring and abundant sedimentary rock consisting of high levels of calcium carbonate (CaCO3) in the form of the mineral calcite. Some limestones may contain small percentage of magnesium carbonate (MgCO3).

of calcium carbonate (calcitic limestone), or a mix of calcium carbonate and magnesium carbonate (dolomitic limestone). Found abundantly throughout the world, limestone has been used for centuries in a variety of applications, including aggregates, building materials, and soil amendments, among others. This handbook focuses on processing ...

Cincinnati/Oftringen, 9 April 2019. Omya, a leading global producer of in-dustrial minerals and a worldwide distributor of specialty chemicals, has become a joint venture partner with Industrias GAT, S.A., a family-owned ground calcium carbonate company located in Haina Municipal-ity, Province of San Cristobal, Dominican Republic.

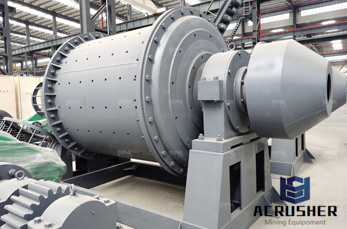

Aug 21, 2018· Grinding and Classifying System for Calcium Carbonate The plant consists of an ALTAI pendular roller mill, a TAURUS ball mill, a SCIROCCO air classifier for fine products and a MISTRAL air ...

Description: Liquidation of machinery previously used at a complete milling operation for calcium carbonate products including limestone. The major equipment includes (3) Raymond Model 6058 Roller Mills with Double Whizzers, Raymond Model 5448 Roller Mill, Raymond Model 3036 Roller mill system, Bartlett Snow 7' x 40' rotary dryer, Madsen 7' x 33' rotary dryer, 4' X 40' rotary dryer ...

The lime industry is a significant carbon dioxide emitter. The manufacture of one tonne of calcium oxide involves decomposing calcium carbonate, with the formation of 785 kg of CO 2 in some applications, such as when used as mortar; this CO 2 is later re-absorbed as the mortar goes off.

Calcium Carbonate is produced commercially in two different grades: Ground Calcium Carbonate (GCC), produced via extraction and processing of naturally occurring deposits; and Precipitated Calcium Carbonate (PCC), produced via chemical processes or as a .

UK calcium carbonates are a nationally significant source of raw materials. Commercial calcium carbonate grades, in the form of powders, granules and slurries, are produced in 2 ways: through the extraction and processing of natural ores or synthetically through chemical precipitation. ...

Limestone, as used by the minerals industry, is any rock composed mostly of calcium carbonate (CaCO 3). Although limestone is common in many parts of the United States, it is critically absent from some. Limestone is used to produce Portland cement, as .

Mar 09, 2018· Lime can be calcium carbonate or magnesium carbonate. They mine a bunch of it in northern Michigan, mostly for steel production. When lime is ground fine, like barn lime, this powder gets to work neutralizing acid in the soil and bringing up the ph so the nutrients are available to the plants.

Aug 22, 2018· Limestone Cycle - limestone, quicklime and slaked lime | Chemistry for All ... Processing Plant for Calcium Carbonate - Duration: 3:11. Ecutec Barcelona 418 views. 3:11.