WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

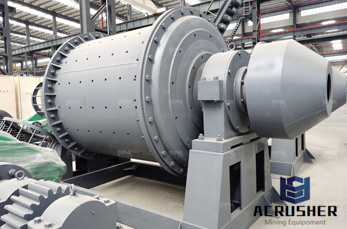

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Conical Ball Mill Rpm. hardinge conical ball mill 75 hp. Ball mills are used primary for single stage fine grinding, . hardage conical mill mining . Get Price And Support Online Ball Mill-Hardinge-Conical - .

CARBIDE TAPERED END MILLS. FEATURES & BENEFITS Every good machinist knows you need all the options you can get to tackle difficult engineering challenges. From varying diameters; stub, regular, long & extra-long lengths, to square end; corner radius & ball ends options, there is a Conical Tapered Carbide end mill.

Martin Chick & Associates CNC Programming Services. Phone - (440) 251-4290 Fax - (440) 639-2838 ... Home. Resources. Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes. Contact. End Mill Speed & Feed Calculator. Tool Dia ...

Tapered End Mills are center cutting, 3 flute high speed steel tools designed for side milling, contouring and machining angled slots. Ideal for use in die cast dies & molds. Solid carbide models are precision ground and inspected to insure complete uniformity and reliability required in the precision mold industry. Available TiAlN coating withstands high heat, allows faster cutting ...

If you're looking for high quality used ball mills to use in your manufacturing processes, you're in the right place. We provide used ball mills at a reasonable price. Both ball and pebble mills work by impact and attrition – a cylinder rotates and moves either balls or pebbles around to grind materials into fine powder.

Hardinge Conical Ball Mill. Diameter: 4.5 ft. Length: 16 in. Shell speed: 29 rpm. 1/2 in. steel plate sell. Wet grind ball mill. Access man hole.

In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding. Presently, for the material being ground, the mill is run at 15 rpm. At what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls, all the other conditions remaining the same? Calculations: The critical speed of ball mill is ...

LMT Onsrud is a leading manufacturer of production cutting tools for the wood industry. We continue to lead the way for natural and composite wood materials.

2002 Quadro Comil Wet/Dry Mill Conical Process Mill U10. One used Quadro Comil, Model U10, stainless steel construction including machine, base, stand, motor, 2 hp, 230/460V motor with VFD controller, up to 3600 RPM beater speed range, mounted on Quadro Unihoist, 100 K...

Jun 19, 2015· The effect of Ball Mill RPM speed going from sub-critical to super-critical helps understand the Ball Mill Working Principles of ball-on-ball VS ball-on-shell grinding. The Motion of the Ball .

Tapered end mills are made from a variety of materials that are chosen according to the degree of precision, hardness, durability and wear resistance required by your application. Cobalt (126) Cobalt is harder than high speed steel and provides better wear resistance.

Conical Ball Mill Rpm hardinge conical ball mill 75 hp Ball mills are used primary for single stage fine grinding, regrinding, and as the mills Gearless. ball mill vs conical ball mill - olle-melin-afrikaturistcoza. hardinge conical ball mill at sibelco-[crusher and mill] Hardinge Conical Ball Mill is used for grinding hard and abrasive ...

Conical Type VS Compartment Type Ball Mills. The Hardinge Conical Mill—because of its conical shape—offsets one of the serious disadvantages found in the cylindrical, compartment type mill, i. e., unproportionate speeds for the different size balls.

The Benefits Promised by Used Hardinge Ball Mill. Harlow Hardinge noticed that rocks of different sizes move at different rates down an inclined surface. This observation led to his development of conical ball mills .

Technical Description. The Hanningfield Uni-Mill U-Series (M05-U, M10-U, M20-U, M30-U) utilises the current industry standard under-driven conical mill design, featuring an IP6X gearbox-driven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

Non-center-cutting End Mills are suitable for peripheral milling and finishing, but cannot be used to make plunge cuts. HSS and Cobalt End Mills will specify if they are center or non-center cutting. Atlas Cutting Tools end mills offer a variety of coatings. Some end mills are uncoated, while others are coated with finishes to enhance performance.

Ball Nose (Conical Ball) Solid Carbide Spiral CNC 2D/3D Carving Tapered and Straight ZrN Coated Router Bits, In-Stock & Ready to Ship Today! Large Selection of ZrN Coated Router Bits.

The geometry of a mill with conical ends is shown in Figure 8.6. The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (8.16) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill.

Our end mills feature various end types, finishes, shapes and flutes and provide an overall smooth machining process. Reliable performance with high speed steel, tapered end mills work for all kinds of cutting jobs, as they are tough and can handle most materials.

The conical ball mill operates on the same principle as an ordinary ball mill; however, due to its conical shaped drum, effective graduate size classification of the grinding media-the section of greatest diameter being the largest for coarser grinding and a gradual reduction towards the discharge end for fine-can be obtained. V-belt or ...

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwide.A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Equipment buys, sells, and trades Used- Hardinge Conical Ball Mill, 9' x 11'. 300 h. Submit a quote for this Ball Mill or call 630-350-2200 for more information.

Ball Nose Mills for Finishing Cuts. Directions: Fill in the blocks shaded in blue with the appropriate information. The calculator will automatically provide the necessary speed and feed in the green fields. For assistance, call Dapra @ (800) 243-3344.