WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel.

How much does an iron ore smelting plant cost. Mettherm provides equipment for Lead Smelting for processing of lead and Consultants" for further queries and total cost setup of a Lead Smelting Plant ... The Itakpe iron ore processing plant in Nigeria presently produces a tail sometimes containing up to waste and at an average concentrate price ...

Oct 27, 2011· This feature is not available right now. Please try again later.

The six-digit Source Classification Code (SCC) for taconite ore processing is 3-03-023. Table 11.23-1 lists the SCCs for taconite ore processing. Taconite is a hard, banded, low-grade ore, and is the predominant iron ore remaining in the United States. Ninety-nine percent of the crude iron ore produced in the United States is taconite.

Rock characteristics for both ore and waste are typical of those of granite or porphyritic material. Operating conditions, wage scales, and unit prices are typical for western U.S. mining operations. All costs listed are in 2012 US$. The key design criteria, operating schedule, equipment, personnel, supply requirements and costs are listed below:

Since its introduction in 1963, the Chemical Engineering Plant Cost Index (CEPCI) has served as an important tool for chemical-process-industry (CPI) professionals when adjusting process plant construction costs from one period to another. The CEPCI consists of .

Oct 19, 2012· COCOA PROCESSING PLANT A cocoa processing plant transforms cocoa beans into three main . Project cost: The project cost will be around Rs. 8 Crores. Turnover and . Stevia chocolate costs upped by fiber blends . counterpart as fiber blends required to give the chocolate structure drive up costs . Processing equipment & plant design ...

Thus the higher capital costs associated with a DMS plant are more easily justified. Alluvial deposits are, in most cases, spread out over a large geographical area and often require the processing plant to be moved in order to remain close to the area being mined so that material handling costs .

Estimated electricity requirements for production of ore from a multi-million t/yr block-caving operation with an underground cone crusher and a 10-mile conveyor belt to the beneficiation plant that produces one concentrate by flotation.....26 Table 9.

How Much does Iron Cost Per Gram?. paymeplease: The cost of iron per gram really depends on what the stock market is looking like when you are ready to buy or even sell. On average iron will cost .

average short haul costs per ton mile aggregate - aggregate .... Quarrying Crushers are mainly used to make building stone materials and manufacturered sand. CGM supplies complete crushing and screening plant for our clients all ...

Jan 01, 2012· The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price. Binders accomplish two very important functions in iron ore pelletization:

Jul 15, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

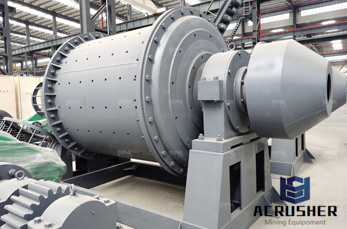

iron ore beneficiation plant cost machinery. ... Cost Of Alumina Crushing And Grinding Machine, used Gold . Laos iron ore processing plant. Laos became one important Southeast Asian market of Birnith since 2005, two years later after the Austria SEPON gold ore processing plant started to work.

recovered from the ore in the EHM concentrator, water is added to the concentrator tailings to form slurry of suitable density for the rougher magnetic separator circuit in the magnetite extraction plant. Ernest Henry Mining: Magnetite Processing For more information contact Vicki Wilson, Senior Community Relations Advisor, EHM on 07 4769 4578.

Iron ore can be extracted underground by using tunnelling and shaft equipment, or it can be sourced at ground level through the use of open pit mines (also known as surface mines). Iron ore is then

flowsheet assessment and capacity evaluation of an iron ore . An iron ore processing plant in Sivas (Turkey) was investigated and owners would be aware of the amount of capital investment, production costs, and the. >> Get Price; Iron Ore Beneficiation Plant Cost. 31 products Alibaba offers 31 iron ore beneficiation plant cost products.

The Itakpe iron ore processing plant in Nigeria presently produces a tail sometimes containing up to 22% iron minerals mostly natural fines in Keywords recovery, fine iron minerals, iron ore processing plant, wastes, blending, dilution, Nigeria. INTRODUCTION waste and at an average concentrate price of ($1,200 per. complete iron ore pellet ...

Energy and Environmental Profile of the U.S. Mining Industry • Agglomerated - The development of techniques of mining and concentrating taconite led to the introduction of the iron-ore pellet. Pellets are comprised of ore that has been agglomerated into balls. The pellet is the major form of introducing iron into the steel-making blast furnace.

The Latest Developments in Iron Ore Processing 5 June ... –Reduce footprint of plant –Deeper troughs –Wider –4-7t/h Spirals. Teeter Bed Separation (TBS) ... Typical Magnetite Processing Circuit Crushing HPGR "212" micron Coarse LIMS max 5 passes Fine LIMS max 5 passes Fine TBS

Mine maintenance - the cost of operation O. Krellis ... average TPH of 1,500 TPH (75% of process TPH) and a process availability of say 55% for 45 weeks per :year, 15 * 8 hr manned shifts and 3 * 8 hr planned ... Conversely, plant and equipment may be running at the right spe~:d and be available but because of excessive wear is

Technical flow of hematite iron ore processing plant. The idea is to know the production process of the dry hematite iron ore processing plant. The hematite iron ore processing plant vegetation is often carefully positioned along with the location on the market to allow for a large amount of recyclable areas. The goal is to keep shipping costs low.

Iron ore pellets are spheres of typically 6–16 mm (0.24–0.63 in) to be used as raw material for blast furnaces.They typically contain 64%-72% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets. Typically limestone, dolomite and olivine is added and Bentonite is used as binder.. The process of pelletizing combines mixing of ...

Oct 19, 2012· Ore Processing Plant Design | Ore Processing Plant cost,Ore . Manganese ore processing equipment for many, mainly . ferrous metallurgy for the total cost, accounting for 15% of the costs of infrastructure and quality of iron ore . Basic Ore Processing | Newmont Mining Corporation. Basic Ore Processing . minerals found within, impact the ...