WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Cement grinding Vertical roller mills versus ball Semantic Scholar to the ball mill system and has increased its share of the market for cement mills over the last decade. There are a number of explanations to this situation, related to issues like cost and ease of operation, cost of installation, cost and ease of maintenance, product quality ...

Cement plant vertical roller mill operational and maintenance News Date:2016-01-05 10:07:11. For several decades the cement industry has successfully utilized Vertical Roller Mills (VRM) for grinding of raw materials and solid fuels. Most recently, this technology has been employed for the comminution of Portland cement, blended cements and slag cements.

vertical cement mill operational data . Vertical roller mill Wikipedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics.

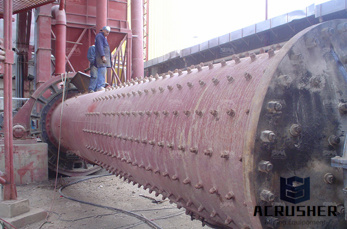

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Vertical Cement Mill Operational Data - devkrupaenterprises. vertical cement mill operation. ball mill cement grinding deshbandhu cement mills limited cement production operation, Working principles of the Vertical Mill pdf . Get Price; cement plant,ball mill,vertical mill,rotary kiln . - CHAENG

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of R&D experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

The advantages of the modular vertical roller mill technology are evident in the results from a case study about a modular vertical roller mill for raw material grinding in operation in North America and detailed operational data of several other 4 and 6 roller mills in operation throughout the world.

vertical cement mill operational data - petwellnesscenter technical data vertical cement mill vertical roller mill is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions, Grinding Mill production mill: Raymond mill, ball mill, vertical pendulum mill, high pressure hanging roller mill, high pressure.

Cement grinding Vertical roller mills versus ball mills. 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. cement factory vertical mill funcfood. cement factory vertical mill: ment, . Cement manufacturing components of a cement .

Vertical Cement Mill In Operation. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. 250tph limestone crushing line in Kenya. 250tph granite crushing line in South Africa. 120tph granite crushing line in Zimbabwe. 400tph crushing plant in Guinea.

Vertical Cement Mill Operation | Crusher Mills, Cone ... Vertical Cement Mill Operation. ... Two years of cement vertical roller mill operation have proven the .

vertical cement mill the operational data specific power of vertical cement mill vertical cement mill operational data, specific power consumption and concrete strength, MLX Vertical Mill Gearbox - NGC Gears Main reducer for MLX280 cement vertical mill used for 4,000T/d cement production lines of Lafarge Yunnan Dongjun Cement Plant .

vertical cement mill the operational data stone crusher machine; vertical roller mill in cement industry ore machine china. sbm cement manufacturing process milling machine SBM Cement manufacturing process milling machine Slideshare 24 Jan 2013 Cement manufacture process ball mill and vertical millball mill and China cement mill is the main ...

The VRM for cement grinding offers a significant advantage in power savings. Typically, the VRM uses 50% less power than a ball mill when grinding the same clinker to 3900 Blaine. VRMs are also much more adept at handling hot feed compared to ball mills.The simple and compact vertical mill layout is cost competitive to build and offers many options for layout, even in existing plants.

Vertical Cement Mill - CHAENG. CHAENG GRMK cement vertical mill gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% ).The vertical cement mill grind materials to related fineness by grinding rollers, you can easy adjusting your product fineness. it can call ...

FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager ... Cement Mill Operating Data 0-7803-9107-1/05/$20.00 (c)2005 IEEE ... Operational Experience from the United States' First Vertical Roller Mill for Cement Grinding Operational Experience from the United States' First Vertical Roller Mill for Cement Grinding ...

typical problems of vertical raw mill | Crusher News. Polysius Roller Mills. For grinding. data from raw . vertical movement and by . Operational Experience from the United . LOESCHE-Mills for cement .

The design of the ready2grind system is based on the Pfeiffer vertical roller mill technology approved across the globe and on the decade-long experience in developing innovative mill technologies. The Pfeiffer vertical roller mill at the core of the ready2grind solution guarantees the highest level of operational reliability

In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a typical energy-efficient Horomill® grinding ...

oped to load and to process industrial data for routine operation of a cement mill, directly extracted from the plant database. In each extraction two days worth of data are loaded, with a sampling period of one minute. Then the software checks for feeder stop-pages and finds continuous operational data sets of 250 minutes duration.

Included in the discussion are operational data, maintenance discussion and. ... The vertical cement mill of CHAENG adopts a new generation of cement ... and rich production experience, and its cement vertical mill has the following advantages: ... of mechanical and .

Operational Experience from the United States' First Vertical Roller ... FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING. By: Mark Simmons ... Included in the discussion are operational data, maintenance discussion and.

vertical cement mill operational data Vertical Cement Mill Operational Data Vertical roller mill Wikipedia, the free encyclopedia Vertical roller mill is a type of . Vertical Cement Mill The Operational Data. reliable plant data (operational, Vertical cement mill is the key equipment to smash after material to be broken Chat Online; Vertical ...

Operational Experience from the United States' First Vertical Roller . ... Working Of Vertical Raw Mill In Cement Plant zgm95g vertical coal mill vertical raw mill cement books pdf free. Get More Info. image ... The same applies to the Design principle and technical data. Vertical roller mill for raw materials.