WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

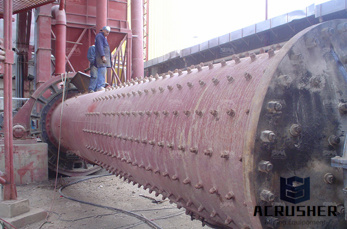

Cement ball mill, cement clinker grinding mill for cement plant. Cement ball mill is used to grind crushed cement clinker, gypsum rock . coal etc. for cement plant.Cement mill in cement production line is of low cost, high capacity etc.

Telephone:0086-371-67666660 Telephone:0086-371-67666667 Contact Person:Mr.Zhao 0086-13523465141 Fax:00086-371—68125111 Well,there is no precise calculation method that can accurately calculate the specific capacity of the cement ball mill.Here are...

Cement industry, power plants - Klingelnberg Employed primarily in the cement industry and in coal-fired power plants, vertical mills are used to grind lime stone, clinker brick, and coal. ... From the initial calculation and design of the gear sets all the way to practical simulations and ...

(4) production capacity calculation of ball mill All the above factors will affect the mill's production capacity, so far there is no calculation formula that can include all these factors, and the exact data must be determined through production practice. Now the common calculation .

Calculate Ball Mill Grinding Capacity View Larger Image The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience.

how to ball mill feed capacity calculate for example_Rotary Air LockRotary airlock dust collector capacity calculation air lock function. US $100 20000 to Compare. Tags: Rotary Air Locks Air Lock For Flour Mill Trailer Air

Dec 06, 2011· Re: how to estimate the wear rate for Ball mill. Dear Mr. Pankaj, Thanks for finding my work on '' Grinding ball pattern software" useful. I have developed few software for cement industry which are listed below. I would like to inform you that these software are .

Jul 22, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

cement ball mill capacity calculation. HeidelbergCement expands cement capacity in Poland – largest ... Mar 28, 2012 ... The new mill, which is the largest ball mill in Europe, has a capacity of 1.4 ... In 2012, total cement capacity in Poland rises to 5.6 million tonnes.

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. 8.1.3 Power drawn by ball, semi-autogenous and autogenous mills A simplified picture of the mill load is shown in Figure 8.3 Ad this can be used to establish the essential features of a model for mill .

Bond ball mill grindability test for overflow wet ball mills. An approach was proposed by Erdem (2002) for dry multi-component cement grinding ball mills, using the results of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a

Calculate Ball Mill Grinding Capacity. A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners)

Composite cement manufacturing is one alternative that is used reduce ... Low grinding kinetics at ball mill compartment 01, suggests improper size grinding media selection ..... 252.5 Improving grinding efficiency in closed circuit cement ball mill. .... 593.5.1 Back calculation of selection function from continuous mill data . Get Price

calculation of cement ball mill capacity - Gold Ore . ball mill capacity calculation,price of ball mill for talc . ball mill capacity calculation. To make the ball mill operate good, we must strictly abide by the . » More; ball mill calculation in cement - crusher in India. Crusher machine.

Calculation Of Cement Ball Mill CapacityCement ball mill, cement clinker grinding mill for cement plant. Cement ball mill is used to grind crushed cement clinke

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALL-MILL SCALEUP Ball-mill scale up (Bond's Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

ball mill capacity tph for iron ore - klabrickellparents. 100 tph ball mill for iron ore fines. 100 tph ball mill for iron ore fines. placer gold mining but also for hard rock mining to recover the 15 30tph and stlb gold concentration separator has a capacity of 60 tph ball mill jaw crusher flotation magnetic separator feeder classifier ore it is a mine separation device for fine minerals ...

Mill Speed - Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

calculation of capacity of cement ball mill micronizing . Calculation Of Cement Ball Mill Capacity 2017-10-25 – Ball Mill. Adapts to capacity, plant layout and end product Learn more The ball mill grinds cement clinke. Get Price And Support Online; MODELING THE SPECIFIC GRINDING ENERGY AND .

Aug 25, 2016· The grinding ball mill grinding capacity calculation Ball Mill Grinding Capacity Calculation grinding ball mill load calculation formula, Gold Ore Crusher . formula to calculate ball mill volume ...

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

calculation of cement ball mill capacity. calculations for efficiency of cement ball mill. calculations for efficiency of cement ball mill. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of ...