WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

SIZE HAMMER MILL AJAKA E.O. and ADESINA A. ... There are four basic ways of reducing the size of materials in the mineral processing industry, these are impact, attrition, shear or compression and most crushers employs a combination of ... Design theories and Calculations Determination of Shaft Speed To calculate the shaft speed the following ...

Jul 01, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

Brazil is the only developing country with a significant synthetic rubber industry. .... Hammer mills or granulators convert the product to rubber crumbs, which are ... Compounding formulas used for natural rubbers are essentially the same as those ..... and ventilation designs, dust exposures are usually well under 2 mg/m3. More details » Get ...

Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. ... Ball nose end mills ... An X added to the code, denotes a cutter version whose pitch is slightly closer than its basic design. ...

This free calculator estimates the number of driving miles between two locations in the United States, and also provides written directions. Use this in conjunction with the gas mileage calculator to plan the gas cost of a road trip, or explore hundreds of other calculators addressing health, .

Dec 12, 2016· The non-reversible Hammer Mill (type 1211) allows the beater heads to be reversed when one side is.calculation of torque of hammer mill - India Hammer Mill Design Calculation Chart Robo Sand ...

Keywords: hammer mill hammers, centre of percussion. Introduction Hammer mills are the essential equipment for herbaceous biomass shredding before compacting as solid biofuel. Hammers are the main working tools of the hammer mill and are rapidly wearing during the hammer mill lifetime. The percussion interaction between the hammer and material ...

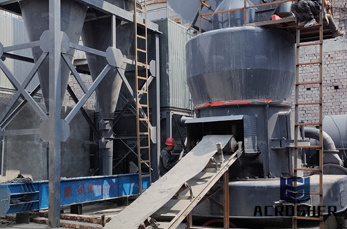

- hammer mills are noisy and can generate dust pollution. General Design The major components of these hammermills, shown in the picture, include: - a delivery device is used to introduce the material to be ground into the path of the hammers. A rotor comprised of a series of machined disks mounted on the horizontal shaft performs this task.

Particle Size and Standard Deviation Roller Mill and Hammermill on Corn US #2 Yellow Corn 300 400 500 600 700 800 900 1000 2 2.5 3 3.5 Roller Mill Hammermill Why process at all? Why process at all? Of course, the answer is ultimately feed efficiency, producing the most milk, eggs, meat or .

Basic Tools Types Applications Precision measuring tools Standard scaled Vernier scaled 3. Tool Identification Basic hand tools 4. Rule Reading Reading standard measurements Making measurement calculations Note: no calculators allowed all tests are timed Skills, Knowledge, and Abilities Test (SKAT .

Formulas and Calculations for Drilling Operations G. Robello ... C1.jpg. Thispageintentionallyleftblank. Formulas and Calculations for Drilling Operations . Scrivener Publishing 3 Winter Street, Suite 3 Salem, MA 01970 . Scrivener Publishing Collections Editors . James E. R. Couper ... 1 Basic Calculations . 1.1 Capacities 1.2 Displacement

When comparing feed grinders for sale, you'll typically find grinder mixers, roller mills, and hammer mills. Grinder mixers use either a hammer mill or roller mill to perform the grinding operation while also allowing for mixing other feeds, minerals, or ingredients into a finished product.

Hammer Mining Mill Power Calculations Israel hammer crusher power calculation –

An empirical equation to estimate the maximum crushing capacity of hammer mills was obtained. The maximum crushing capacity measured was on an average about 1.5 times larger than the value calculated from the empirical equation. However, the approximate estimation of the maximum crushing capacity of hammer mills was possible.

calculation hammer mill design pdf . calculation hammer mill design pdf - feniksorkest. basic design calculations of hammer mill -, hammer mill design calculation hammer crusher design and calculation-Mining Equipment For Sale method of calculation of, pdf hammer mill design calculation -

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

3Water hammer Pressure transients are also re-ferred to as surge pressure or, if referring to water systems, water hammer. The latter term suitably reflects the harmful effects that the hammer-like blows accom-panying the pressure surges can have on pipes and system com-ponents. Water hammer causes piping, valves, pipe fixtures, sup-

Milling, Grinding & Flaking Every detail counts. The roller mill is by far the most important grinding machine in a mill. Whether processing maize, wheat, durum wheat, rye, barley, or malt – offers the ideal roller mill for processing all grain varieties The process used to produce flour in a mill is referred to as a gradual reduction.

Hippo Hammer Mills. Hippo hammer mills rapidly pulverize a wide range of materials from beans, wheat, corn, minerals, plastics, glass and bone to coffee beans, herbs and fibrous roots. Materials enter the milling chamber and are impacted by hammers rotating at high speed.

hopper and the hammer mill was switched on. The grinding tin was noted. This was repeated for four times and averages used for calculation. Test Using Dry Maize The same procedure was reported using 5 kg of dry maize Results and Discussion Table 1. Hammer mill test results using cassava Trial Mass of cas- sava before grinding (kg) Mass of ...

Instructions How To Use a Milling Machine. Therefore, the RPM for a l/2-inch-diameter end mill machining aluminum revolves at 2,400 RPM and the feed rate should be 24 inches per minute.

The conveyor belt calculations methodology discussed in the article is to be used only for the guidance on calculating the initial conveyor design parameters; the final design must be validated by using the FEA or other similar tools before building the prototype. Reference. Dunlop – Conveyor belt technique design and calculation

Small grain hammermills can be operated on current. Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 to over 5000 horsepower (1.5 - 3.7MW). The screenless hammer mill uses air flow to separate small particles from larger ones. It is designed to be more reliable, and is also ...