WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with ball mills.

SikaGrind® FOR VERTICAL ROLLER MILLS 3 In a ball mill, the particles are ground by repeated impact forces. The material needs usually more than 20 minutes from mill entrance to outlet, uncountable impacts take place on this way. Depending on the efficiency of the separator and the Grinding

improve throughput of vertical roller mill educationcare. Improving the performance of Loesche's Vertical Mill 3 at Nuh Mar 19, 2012 The mill is a vertical roller mill from Loesche. Nuh Cimento Sanayi's goal was to increase the throughput of the mill with reduced energy use.

Improving Performance of. Vertical Roller Mills. Using Advanced Process Control and Real Time Optimization Steve McGarel Loesche Germany. Operational Challenges in the Plant Cost efficient production despite rising energy, labor and material costs Increase throughput and maintain process stability to improve power efficiency

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. 2.3 Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills.

Separation operation of vertical-roller-mill will be modelled by application of current models. The model shall enable the prediction of the throughput, the particle size distributions around the vertical-roller-mill circuit, the specific energy consumption and in a later .

Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement lines. The limits of material throughput of VRMs are, unlike other mill types, not defined by the comminution process itself but by the transmissible torque of the drive train. Therefore the size of. CONTINUE READING

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

improve throughput of vertical roller mill - rrcser. Improving the performance of Loesche's Vertical Mill 3 at Nuh . Mar 19, 2012 . The mill is a vertical roller mill from Loesche. . Nuh Cimento Sanayi's goal was to increase the throughput of the mill with reduced energy use.

This excessive size reduction is counterproductive. Energy is wasted in the production of heat, throughput is restricted, and particles become too small. Most newer hammermills are equipped with an air-assist system that draws air into the hammer mill with the product to be ground.

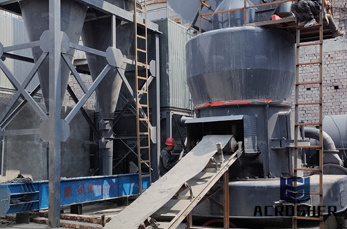

uses the test-roller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for granulated blast furnace slag grinding in China. Roller mill for cement raw material grinding in China. Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland.

Mar 07, 2013· LM-Master for Vertical Roller Mills 1. FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USALMmaster_forVRMsdd 1 19.06.12 11:46

will running a crusher mainshaft faster improve throughput. improve crusher performance throughput . will running a crusher mainshaft faster improve throughput. VSI5x Crushing Equipment Main Features rotor of vsi5x crusher improve the material throughput by, will running a crusher, the crusher performance . ... how to improve coal crusher ...

Energy-Efficient Technologies in Cement Grinding. ... (roller presses), Horomills, high-efficiency classifiers and vertical roller mills (VRM) for clinker grinding which are more energy efficient than machinery which has been in common use for many years such as tube mills. ... Roller mills are operated with throughput capacities of more than ...

HLM vertical Mill uses standard modules to design and fabricate pressurization device. With the increase in mill capacity, there is an increase in roller numbers (we can use 2,3 or 4 rollers, 6 rollers maximum) in proper permutation and combination to form the series of equipment of various capacities with minimum standard parts in order to ...

is included to improve feedback to the control application and boost overall production performance. Operation of open circuit, closed circuit, roller press-ball mill combinations, as well as vertical roller mills, is improved through application use. Energy Usage Real-time .

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_forVRMsdd 1 .

Mar 10, 2015· In addition the settings of the apparatus can be adjusted to an optimum with respect to the specific energy consumption by increasing the throughput rate to a maximum at stable conditions for the vertical roller mills and by using the optimized comminution sequence for the tumbling mills.

will running a crusher mainshaft faster improve throughput this type of improve throughput of vertical roller mill improve crusher performance throughput increase mill throughput grproperties Nov 07, 2012· improve throughput of vertical roller mill Improving Crusher and Mill Throughput and Recovery by Improving Fragmentation.

Improve Throughput Of Vertical Roller Mill. Performance Of Vertical Roller Mill . Feb 17 2016 In this training module well cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feed W Vertical roller mill for raw materials The vertical roller mill has high energy efficiency and the installation space is .

Loesche developed the 4-roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The develop-ment was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair of rollers to increase control response availability and flexibility.

improve throughput of vertical roller mill educationcare. Improving the performance of Loesche's Vertical Mill 3 at Nuh Mar 19, 2012 The mill is a vertical roller mill from Loesche. Nuh Cimento Sanayi's goal was to increase the throughput of the mill with reduced energy use.

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for dry-grinding the above-mentioned grinding stock. Loesche has developed and built the largest and most

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Cement mills and raw mills for high throughput rates